PVC Sheet extrusion line

PVC Composition and characteristics of sheet production line

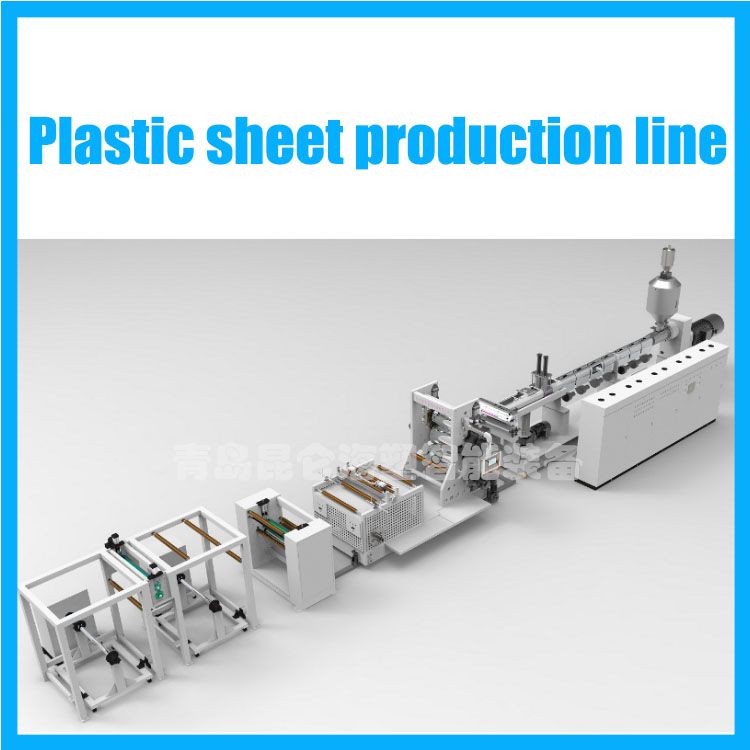

PVC plastic sheet equipment is mainly composed of single (double) screw extruder, hanger type mold, three roller setting machine (setting table), Calender (optional), cooling traction bracket, plate shearing machine, winding machine and other auxiliary machinery.PVC plastic sheet equipment can produce single or multilayer co-extrusion sheet.PVC plastic sheet equipment can also produce all kinds of PS sheet, PVC sheet, PC sheet, PE sheet, PET sheet, etc.

PVC Sheet equipment process flow:

Precrystallization of raw materials→ materials are heated, transported and compressed by extrusion machine → materials are dispersed, mixed and homogenized, and then input into filter and flat extrusion die head with stable pressure → solution filtration → solution homogenization and stable pumping out → co-extrusion distribution and homogenization and layering → even distribution and quantitative stable extrusion of solution in die head → die forming → three roll pressing, cooling and shaping → cutting waste edge to Required width and size → natural cooling conveying sheet → hand rolling scrap edge → stable traction sheet → winding sheet

PVC features and application of sheet materials:

PVC sheet has high strength, good temperature resistance and good corrosion resistance.The addition of additives can increase the strength, toughness, hardness, flame retardant and printing requirements.PVC extruded transparent sheet has the characteristics of flame retardant and self extinguishing, high quality and low price, high transparency, good surface gloss, less crystal point, small water mark, strong impact resistance and easy molding. It is widely used in the blister, folding box and packaging of various tools, toys, electronics, food, medicine, clothing and other industries.

| Name | Uniy | Model | ||

| 600 | 800 | 1000 | ||

| Screw diameter | mm | 80/156 | 80/156 | 92/188 |

| Aspect ratio | L/D | 33/1 | 33/1 | 33/1 |

| Sheet width | mm | 600 | 800 | 1000 |

| Sheet thickness | mm | 0.12-2.0 | 0.1-2.0 | 0.01-2.0 |

| Traction speed | m/min | 1-25 | 1-25 | 1-20 |

| Yield | kg/h | 280 | 280 | 300 |

| Motor Power | kw | 55 | 55 | 75 |

| Heating power | kw | 80 | 80 | 90 |