Brief introduction of PVC wood plastic wallboard production line

PVC wood plastic wallboard production line adopts automatic control, with high degree of automation, stable equipment, simple operation and high production efficiency. By changing the mold of different specifications, we can produce various specifications, sizes, shapes and thicknesses of wood plastic decorative wall panel, wood plastic wall panel, quick installation wall panel and ecological wall panel.

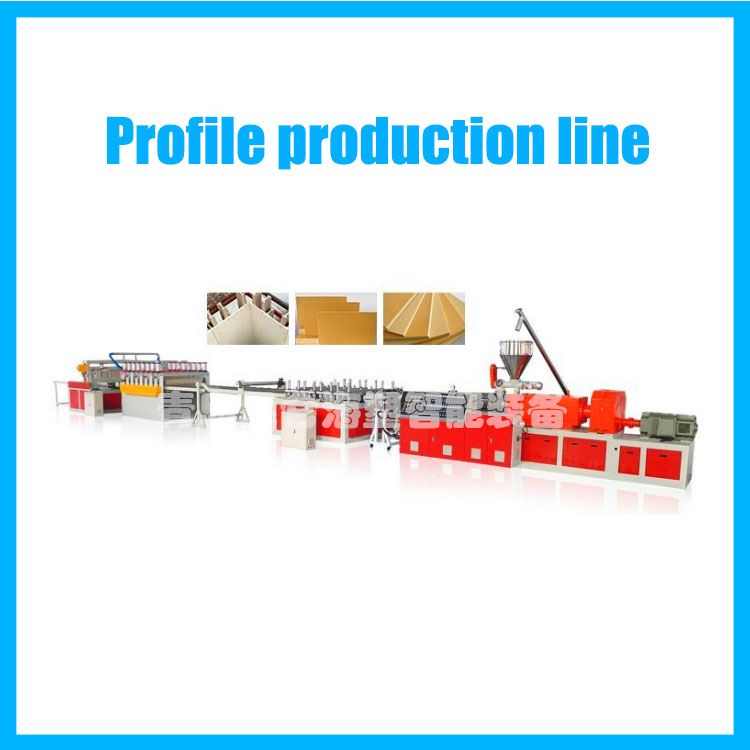

Components of PVC wood plastic wallboard production line

① Cone double host machine

② coextrusion machine (optional)

③ vacuum setting table

④ traction machine

⑤ cutting machine

⑥ automatic material receiving rack

Characteristics of PVC wood plastic wallboard production line

1. The wood plastic decorative wall panel has the same processing performance as the log, which can be nailed, drilled, cut and bonded. The surface is smooth and exquisite, and there is no need for sanding and painting.

2. Wood plastic decorative wallboard has better physical properties than logs, better dimensional stability than wood, no cracks, warpage, no wood knots, twills, adding colorants, film or composite surface can be made into colorful products, so there is no need for regular maintenance.

3. Wood plastic decorative wallboard has the advantages of fire prevention, waterproof, corrosion resistance, moisture resistance, no moth, no fungus, acid and alkali resistance, no harm, no pollution and so on.

4. Wood plastic decorative wallboard has similar wood appearance in use, higher hardness than plastic, long life, can be thermoplastic molding, high strength, energy saving. The product is solid, light weight, heat preservation, smooth surface and no pollution.

| Model auxiliary | Small timber production line | ordinary production lin | high speed production line | quasi high speed production line |

| Number of vacuum joints | 30 | 30 | 40 | 40 |

| Length of setting table | 3000mm | 400mm | 4000/5000mm | 6000/8000mm |

| Maximum traction kn | 20 | 30 | 40 | 40 |

| Maximum traction speed M / min | 8 | 3 | 5 | 5 |

| track width mm | 200 | 240 | 240 | 240 |

| Cooling water M3 | 2.5 | 4 | 5 | 6 |

| Gas consumption m3 / h | 8 | 10 | 12 | 15 |

| Total power kw | 24.3 | 27 | 33.5 | 34.5 |