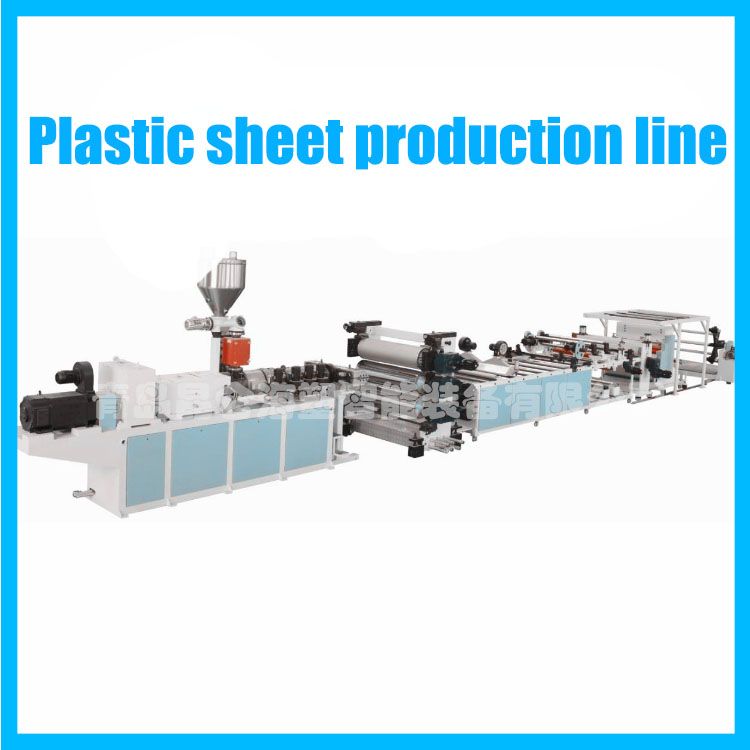

Introduction of PE / PP sheet extrusion line

PE / PP single and multi-layer composite sheet production line can be used to produce 0.3-5mm PP and PE sheet. It is mainly composed of single screw extruder, mold , three roll calender, traction machine, winding machine or cutting machine.

Configuration and features of PE / PP sheet extrusion line

1. The screw of sheet extruder is designed with special mixing function and high plasticizing capacity to ensure the melting of plastics, uniform color and high extrusion volume.It is designed with special mixing function and high plasticizing capacity.

2 The special variable throttle design is adopted for the hanger die head, which makes the adjustment of plate thickness more accurate.

3 Roll forming roller table adopts horizontal or vertical type, which can be lifted and lowered freely, which is convenient for adjusting sheet thickness and improving sheet quality.

4 The sheet winding device adopts four axes, and the automatic tension control of advanced special moment motor can adjust the speed and tension at will to achieve the flatness of sheet rolling.

5 The temperature control error is 1 ℃, and the plasticizing process, sheet thickness and flatness can be accurately controlled.

6 Plastic sheet extruder hanger die head adopts special double section flow design, which makes plate thickness adjustment more accurate.Temperature control plus or minus 1 ℃ can accurately control the plasticizing process, thickness and flatness of the plate.

7 Three roller calender adopts vertical or 45 degree inclined type, which can be lifted and lowered freely.The thickness of sheet can be controlled precisely by screw adjustment and press wheel bidirectional adjustment.

Application scope of PE / PP sheet extrusion line

PE / PP is widely used in product packaging, food packaging, stationery, printing, gift and craft products manufacturing due to its high strength, high temperature resistance, good corrosion resistance, filling, reinforcement, toughening, flame retardant, modification, surface embossing, sanding and other characteristics.The main products are: gift bags, advertising fans, document bags, lampshades, mouse pads, food packaging boxes, etc.

| Name | Unit | Model | ||

| 800 | 1000 | 1500 | ||

| Screw diameter | mm | 100 | 105 | 120 |

| length diameter | L/D | 33/1 | 33/1 | 33/1 |

| sheet width | mm | 700 | 900 | 1400 |

| sheet thickness | mm | 0.12-2.0 | 0.1-2.0 | 0.01-2.0 |

| Traction speed | m/min | 1-25 | 1-25 | 1-20 |

| output | kg/h | 150 | 220 | 250 |

| monitor rate | kw | 37 | 45 | 75 |

| Auxiliary power | kw | 4.5 | 5 | 5 |

| heating power | kw | 80 | 90 | 90 |