Corrugated pipe production line

HDPE / PVC double wall corrugated pipe production line

Brief introduction of HDPE / PVC double wall corrugated pipe production line

The (φ 200 - φ 600) HDPE / PVC double wall corrugated pipe extrusion line has the advantages of high output, stable extrusion and high automation.

Configuration and characteristics of HDPE / PVC double wall corrugated pipe production line

1.Extruder: the extruder can be specially designed according to the user's raw materials. HDPE adopts high-efficiency single screw extruder, and PVC adopts large parallel twin screw or conical twin extruder.

2.Molding machine:it adopt horizontal structure, chain drive design, equipped with forced air cooling system, greatly improve the production speed, module operation using advanced mechanical up and down synchronous drive system, to ensure the operation accuracy, ensure the stability of the quality of pipes, advanced automatic lubrication system to minimize the wear of molding module and bottom plate, greatly extending the service life.

3.extruder’s die : With compound extruder die and be made of 40Cr, chrome plated and polished.The inner and outer wall thickness is uniformed and the molding is stable.

4.Cutting machine: automatic cutting, it has effect of good cutting effect, high speed, low noise and no pollution.

5.Production line control system: the whole production line adopted PLC microcomputer control system to display melt temperature, pressure, molding speed, fault alarm, etc.The operation interface adopts multiple pictures, and has the basic process storage function.

Application scope of HDPE / PVC double wall corrugated pipe extrusion line

Double wall corrugated pipe (outer diameter Φ 63 - Φ 250mm) is made of PVC.Its structural design is new and reasonable. It is composed of smooth inner wall and hollow corrugated outer wall. It has good ability to bear external load. It has the advantages of high strength, light weight, smooth inner wall, impact resistance, corrosion resistance, convenient construction and low cost.The product adopts flaring socket and sealing ring connection, which can prevent the influence of thermal expansion and cold contraction.Double wall corrugated pipe is widely used in highway, railway subgrade, subway engineering, waste landfill, tunnel, green belt, sports field and slope protection caused by high water content.

| Model | BW-IV | BW-IVseries | BW-IV A | BW-IV Aseries |

| Power | 11KW | 11KW | 15KW | 15KW |

| Mould specilication | Φ200mm-Φ400mm | Φ200mm-Φ400mm | Φ300mm-Φ600mm | Φ300mm-Φ600mm |

| Mould material | Special aluminum alloy | Special aliuminum alloy | Special aliuminum alloy | Special aliuminum alloy |

| Mould perimeter | 7m | 7m | 7m | 7m |

| Mould cooling way | Air cooling | Air cooling | Air cooling | Air cooling |

| Production speed | 0.5m-0.2m/min | 0.5m-0.2m/min | 0.5m-0.2m/min | 0.5m-0.2m/min |

| production material | PVC/HDPE | PVC/HDPE | PVC/HDPE | PVC/HDPE |

| Main machine | Singletwin screw barrel extruder | Twin-screw extruder/single screw extruder | Concial extruder | Twin-screw extruder/single screw extruder |

Single wall corrugated pipe production line

Brief introduction of single wall corrugated pipe production line

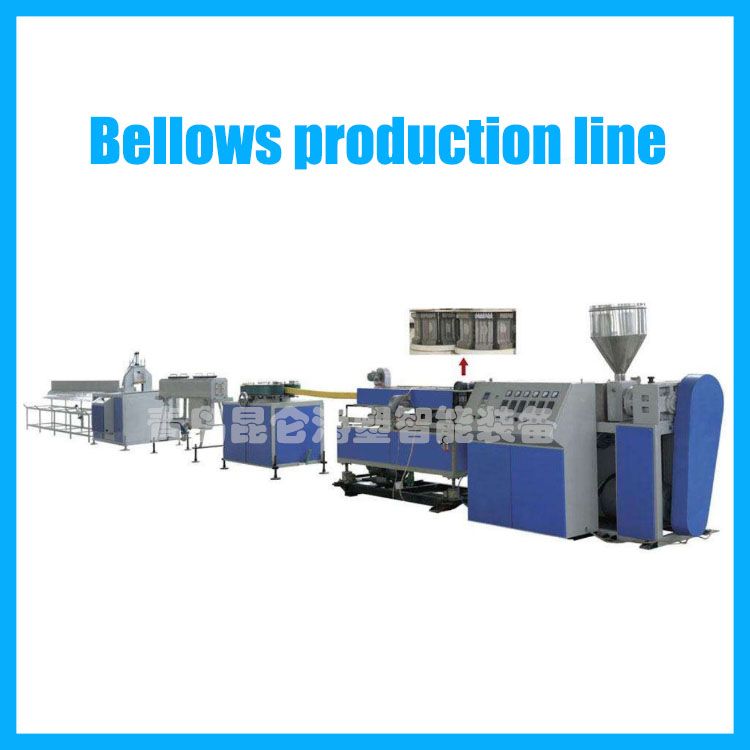

The single wall corrugated pipe production line is composed of extruder, extrusion die, molding machine, cooling device, auxiliary traction machine, sawing machine and reversing table.

Configuration and characteristics of single wall corrugated pipe production line

1. The machine mainly uses PVC, PP, PE as raw materials to produce small diameter single wall corrugated pipe.

2. The corrugated pipe products with smooth inside and outside and uniform ripple can be formed by the corresponding mold at one time.

3.The forming machine and head have high precision and good interchangeability.

4.There are two kinds of module cooling: water cooling and air cooling.

5.It can realize on-line expanding.

6.The whole line adopts unique digital control system.

7.High automation, high output and stable operation.

Application scope of single wall corrugated pipe extrusion line

Single wall corrugated pipe can be used as water pipe, gas pipe, threading pipe, wire protection pipe, wire and cable threading pipe, washing machine drainage pipe, vacuum cleaner pipe and ventilation pipe.

Single wall corrugated pipe production line

Brief introduction of single wall corrugated pipe production line

The single wall corrugated pipe production line is composed of extruder, extrusion die, mold , cooling device, auxiliary traction machine, sawing machine and reversing table.

Configuration and characteristics of single wall corrugated pipe production line

1. The machine mainly uses PVC, PP, PE as raw materials to produce small diameter single wall corrugated pipe.2. The corrugated pipe products with smooth inside and outside and uniform ripple can be formed by the corresponding mold at one time.

3.The forming machine and head have high precision and good interchangeability.

4.There are two kinds of module cooling: water cooling and air cooling.

5.It can realize on-line expanding.

6.The whole line adopts unique digital control system.

7.High automation, high output and stable operation.

Application scope of single wall corrugated pipe extrusion line

Single wall corrugated pipe can be used as water pipe, gas pipe, threading pipe, wire protection pipe, wire and cable threading pipe, washing machine drainage pipe, vacuum cleaner pipe and ventilation pipe.

| Model | Supporting host | Modules Quantity | Pipe specifications |

| XDCSB50 | SJ45/30 or SJ-65/30(PVC) | 40 | Φ6-50mm |

| XDCSB160 | SJ90/30 SJSZ-65/132(PVC) | 48 | Φ75-160mm |

| XDCSB500 | SJ120/30(PE) SJSZ-92/188(PVC) | 42 | Φ200-500mm |