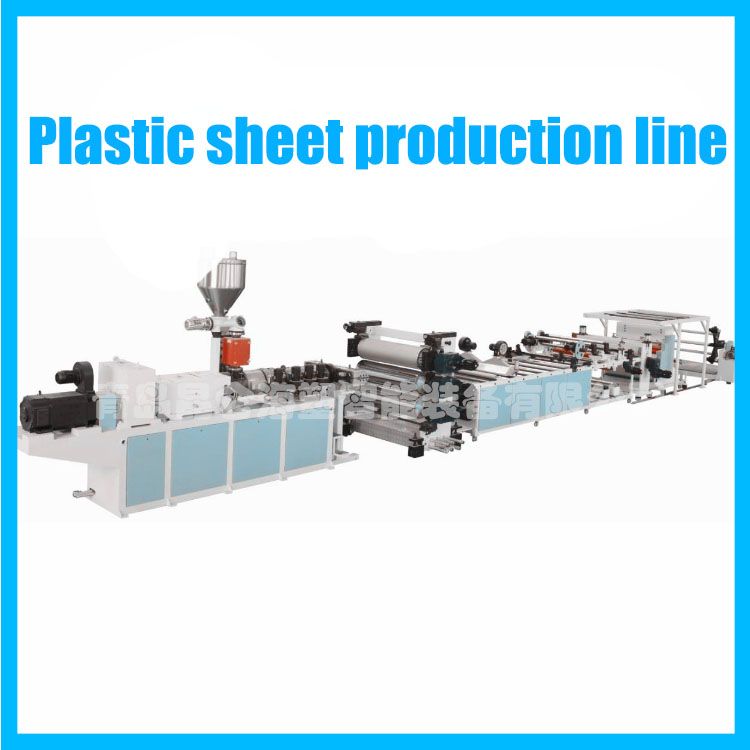

Introduction of PS sheet extrusion line

The production line is mainly suitable for the production of PS plastic sheet (plate).After replacing the die of the main engine, the processing of PVC, PMMA, PC and other plastic sheets can also be carried out. After the auxiliary equipment such as drying is added, pet processing can be carried out.Processing range: thickness 1-20mm, width 600-1800mm.

Configuration and features of PS sheet extrusion line

1, extruder using large length diameter ratio screw, plasticizing effect is good.

2. The die head net changing part adopts hydraulic quick screen changing device without stopping the machine, which is easy to operate and has high production efficiency.

3. The die head adopts internal heating type, which has the advantages of easy mold adjustment, uniform film thickness, uniform flow rate, high heat utilization rate and save electricity.

4. The slicer adopts microcomputer and hydraulic control to realize automatic work of fixed length slicing and counting.

Application scope of PS sheet extrusion line

Application scope of PS sheet: daily necessities, decoration, product packaging, food packaging, etc.

| Applicable plastic | PS/PE/PP/ABS/TPU... |

| Sheet width | 500-720mm |

| Sheet thickness | 0.3-2.0mm |

| Production capacity | 150-180kg/h |

| Total power | 150kw |

| Working power | 60kw |

| Voltage requirements | 380v,3phase,4line |

| Total Weight | 4ton |

| Dimensions | 11m*1.5m*2.3m |